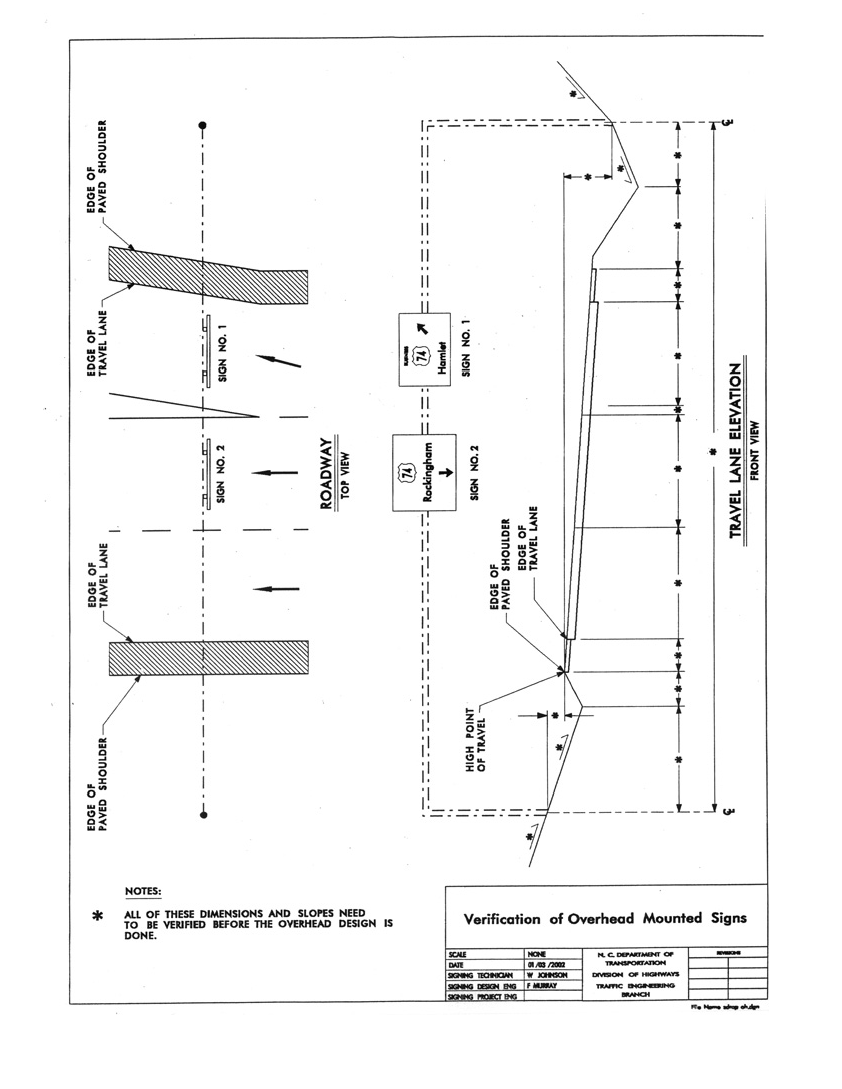

Checking the information on overhead sign assemblies in the field will consist of “S” dimensions at the center of the structure upright supports, cut or fill slopes, and pavement width information. The “S” dimension for overheads is different from that of ground mounted signs. The elevation of the center of the upright is from the high point of the road. This includes paved shoulders, mountable medians, future lanes, or any point that a vehicle could physically drive on under any sign on the overhead structure. The side slope is the slope at the centerline of the uprights and at least

2 feet on both sides. Both the “S” dimension and the slopes are used by Structure Design to check the footing design. The width of each lane or part of a lane, shoulders, and the offset to the uprights should be verified. This is the cross section that the contractor will have to construct. See attached drawing on the proceeding page for clarification.

Verifications of these dimensions must be made before supports for the ground mounted or overhead signs can be ordered by the contractor.

STRUCTURE STAKEOUT

Structure and Roadway plans should be studied together prior to beginning staking in order to become familiar with the planned work, to establish where reference points may be placed and remain undisturbed, to check lengths of box culverts as required on the culvert plans, and to check and recalculate slope, roadway widths, and elevations common to structure and adjacent roadway.

During stakeout and construction of the structures, bound field or level books shall be used for structure work books in which shall be recorded: diagrams and sketches showing location of construction stakes set; complete level notes of elevations set for all parts of the structure and grade hubs; the names of all those doing the survey work, what each person did, and the date the work was done.

Structures should be staked using the most accurate equipment and methods at the Resident Engineer's disposal. Total stations are preferred. Radial Stakeout should not be used for major structure stakeout. Control lines to be staked and referenced for bridges are: centerline or long chord line, end bent fill face lines, and interior bent centerlines, or other designated work lines. For box culverts the lines are: centerline of culvert and ends of barrel. Offset grade hubs should also be set for culverts. Hubs with tacks and clearly marked guard stakes shall be used to reference these lines.

The

Manual For Construction Stakeout should be followed. There is also a

Structure Layout video on the NCDOT YouTube channel.

The sketches represent typical bridge and culvert layouts. They should be varied to suit individual cases. The links to the sketches can be found here:

Checking Layout

When a structure is staked out by NCDOT staff, Resident Engineers and Party Chiefs should develop a systematic scheme for checking a structure stakeout both during the stakeout and after the structure has been laid out. Each measurement, whether a distance, angle turned, or elevation given should be checked. One scheme that will serve to check the work is to let entirely different personnel check the layout. Another practical way to check the layout is to change roles within the survey party and perform a check of the layout. This method will also serve to provide additional experience and training for party personnel. When stakeout is performed by Contract Surveyors, an NCDOT survey party should perform a check of the structure layout.

Engineering Practices To Follow

- Check instruments periodically for accuracy.

- Check alignment stationing in the field from two independent references.

- Check bench marks in the field from two independent references. All bench marks which are established for use during construction should be, as nearly as practicable, of a permanent nature. Check bench marks used for structure construction with bench marks used for roadway construction. When setting bench marks, avoid setting them in deep embankments that have not set for several months or in any embankments in the vicinity of anticipated pile driving operations. This can be an inconvenience, but problems can arise due to settlement of the bench marks. Levels can be run from bench marks in other areas and temporary bench marks set, or checked, each time critical elevations are necessary, or at least once a week while in use except when pile driving has been taking place. If pile driving has taken place in the vicinity, the temporary bench marks set in embankments should be checked at least daily when in use.

- Completely stake structure when practicable before construction begins.

- Systematically and uniformly identify all points with clearly marked guard stakes.

- Set extra points to facilitate replacing those destroyed.

- Check railroad rail elevations against bottom of beam elevations at railroad separations during stakeout and compare difference in elevations to vertical clearance shown on plans.

- Check cut and fill slopes at end bents during and after grading but prior to starting structure construction.

- Immediately prior to casting the cap of a substructure unit, elevations are to be checked on the chamfer strip for each bridge seat. Immediately after all concrete in the cap has been cast, another check is to be made at each bridge seat using an independent set-up of the instrument. Any falsework slippage or excessive settlement will then be apparent. After the first substructure unit has been completed, both of the above checks shall include a check on a bridge seat of a previously cast cap. All rod readings and computations for the above shall be recorded, dated, and initialed in the structure field book.

- Check camber in beams and girders after they are erected but before connections are tightened. Beam camber shall be corrected to conform to

12 millimeters (1/2 inch) for proper tolerance.

- Check bridge slab thickness when

the dry run is performed.

- Check projection of shear studs into slab.

- Slope protection berm width should be computed prior to slope staking the ends of the bridge fills. The toe of the slope protection should be staked to insure that alignment and grade will conform with that of the roadway.

- It is usually good practice to establish a temporary bench mark on a substructure as soon as it is completed. This is usually accomplished by setting one temporary benchmark on a wing wall of each end bent.

- Check top of pavement elevations against bottom of beam elevation at flyovers during stakeout and compare difference in elevations to vertical clearance shown on plans to insure it is sufficient.

SUGGESTED PROCEDURE FOR GRADING BUILD-UPS ON CONTINUOUS OR SIMPLE SPAN BRIDGES

Final bottom of slab elevations at

twentieth points between centerline of bearings are furnished by the

Structures Management Unit. The elevations are given along the centerline of each girder and are used in computing the height of the build-ups. There is a video entitled

Bridge Deck Buildups on the NCDOT YouTube channel.

Build-up height is fixed at the centerline of bearing and would be constant throughout the length of a span if the actual girder camber was exactly as shown, but the build-ups will normally vary in height between bearings.

Tops of girders should be marked with paint at each twentieth point. (For longer spans 40th or

60th points may be required – see construction elevations provided from the Structures Management Unit.) After camber has been checked, necessary corrections made, and diaphragm connection bolts tightened, elevations should be determined on top of girders at each twentieth point and used in computing build-up heights. The effect of the sun can significantly change girder camber. Levels should be run either early in the morning or on a completely overcast morning. Deflections shown in the deflection tables are used in the required computations. Build-up height at a twentieth point is computed as follows:

+ final bottom of slab elevation

+ deflection due to weight of slab

+ deflection due to weight of parapet, rail, and F.W.S.

- top of girder elevation (determined in field)

The algebraic sum of these values equals the height of build-up above the top of girder. In some cases, this value will be minus indicating the girder flange projects into the slab. In such cases the Area Construction Engineer should be consulted.

The build-up heights for the entire bridge can be computed and listed in a field book well in advance of any forming operation. These heights can be marked on the top of girder at the proper twentieth point.

The Contractor should be made aware that the computed height is at the centerline of girder and will vary at each side of the build-up depending on the deck cross slope and flange width.

Theoretical overhang elevations are no longer supplied and should not be used to grade overhangs.

Overhangs can be graded very efficiently by using the overhang typical section and adjusting by a small amount of form settlement and compensating for build-ups on the top of the exterior girders or beams. This can be done either with a “preacher” or checking the algebraic difference from the buildup to the overhang with an engineer’s level. There is a video entitled

Overhangs on the NCDOT YouTube chanel.

It should be noted that bridges with normal crown and similar overhangs on both sides can be graded using one typical section with the algebraic difference between the bottom of slab over the exterior girder or beam and the outside bottom edge of the overhang. A structure with constant superelevation will require two typical section computations. A structure with variable superelevation or varying width overhangs, such as those found on horizontally curved bridges with straight girders, will require a different typical section computation at each grade point if the superelevation or overhang width changes.

Regardless of grade point spacing, all overhang brackets or jacks should be graded. A quick interpolation between grade points, with adjustment for top flange thickness when it changes, can be easily calculated. String-lining between graded jacks to set other jacks is also acceptable.

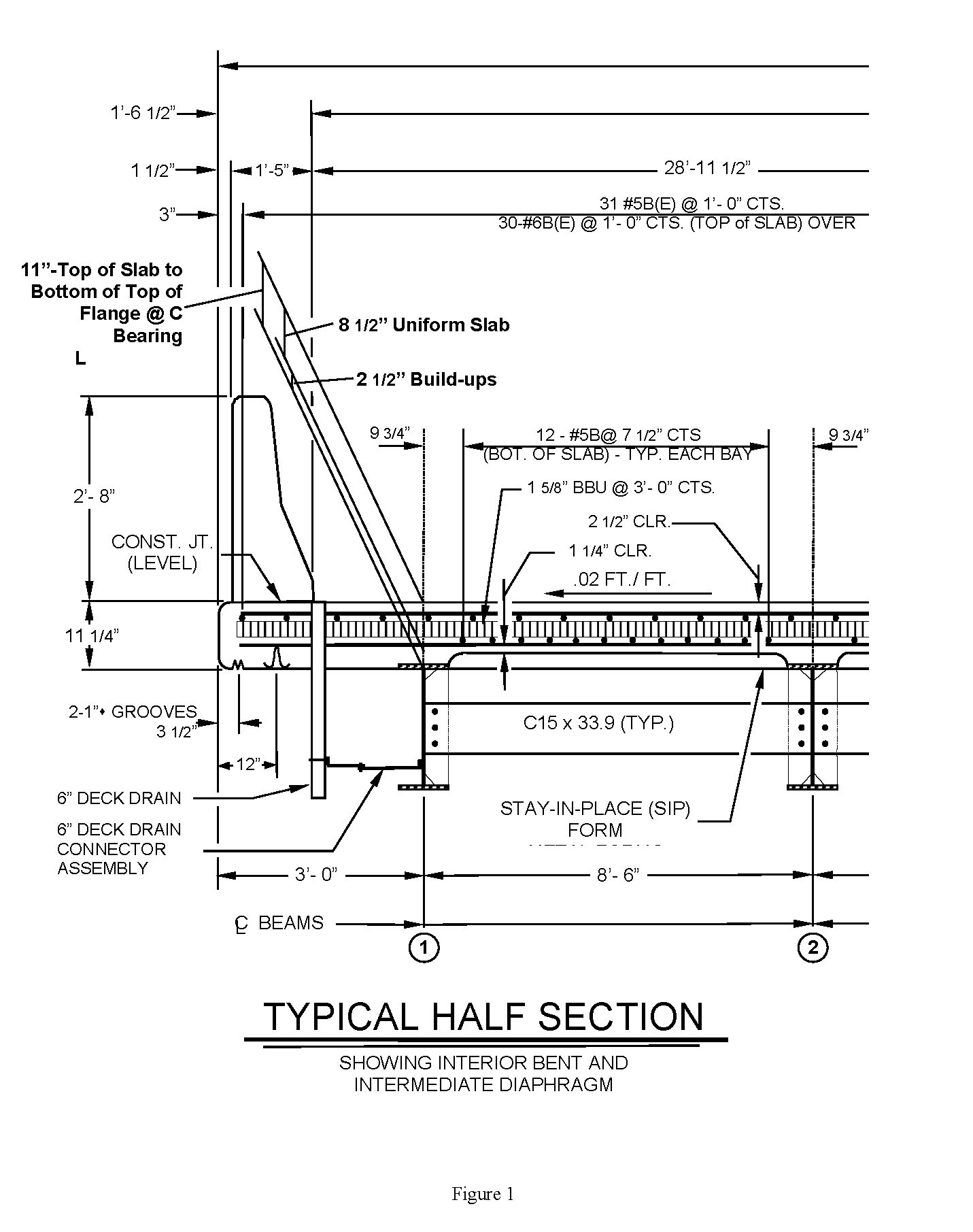

Following is an example in English Units of using this method to grade overhang formwork: See Figure 1.

![]()

Step 1 - Compute algebraic difference between bottom of slab and outside bottom edge of overhang:

Therefore, grade for an overhang point opposite a field build-up of

+0.12 = -0.24 + 0.12 = -0.12 below the top of beam or girder.

Beginning in April 2017 the construction elevations were revised to provide the algebraic difference between the bottom of the slab over the centerline of the exterior girder and the outside edge of the overhang, eliminating the calculations above , with the exception of adding in form settlement. The construction elevations would give the difference of -0.26’, and the +0.02 form settlement would then need to be added.

Given this information the algebraic difference between the top of the girder and the overhang grade is easily determined. Assuming the buildup at this location was 0.33' you would add the -0.26' above to the buildup, resulting in a difference of 0.07' from the top of the girder to the bottom of the overhang.

The construction elevations also show the distance from the centerline of the exterior girder to the overhang. This information is especially useful when laying out the overhangs on a curved bridge with straight girders. In such cases that the overhangs are laid out in this way you should pull a string down the center of the girder from bearing to bearing to locate the theoretical center of girder. This is necessary due to potential sweep in the girder.

Step 2 - Show overhang grades in structure workbook opposite build-up grades and adjusted to level over from top of beam or girder with the use of an engineering level and rod or a carpenter level and rule. Interpolate in between grades to adjust each overhang bracket or jack to assure uniform grade. It is acceptable to string line between jacks at twentieth points which have been graded, to grade intermediate jacks. All grades can be computed and checked in the structure workbook well ahead of time.

The reason construction theoretical grades should not be used (and are no longer included in Construction Elevations) is to eliminate the effects temperature changes and the constant movement of girders or beams. Using typical sections will assure all overhangs are relative to the girder or beam and therefore a constant slope will be attained on the bottom of overhangs. In an extreme case, it would be possible to have a reverse slope on the overhang bottom if the girder or beam has moved sufficiently down and a theoretical elevation is used.

SUGGESTED PROCEDURE FOR GRADING HEADERS

As of April 2017, header grades are no longer supplied in the construction elevations. Better results are observed when the transverse screed is graded as outlined below and the header is left 1-2” low. The screed is allowed to finish over the header to the proper grade.

If the contractor elects to use a longitudinal screed contact your Area Construction Engineer for guidance on setting header elevations.

SUGGESTED PROCEDURE FOR GRADING SCREEDS

A. Transverse Screed

After overhang forms have been graded, the screed rail can be adjusted to some predetermined constant height above the bottom form at the outside edge of overhang. A gage stick and carpenter's level can be used in adjusting the screed rail to the proper elevation.

The screed carriage must be graded to conform to the transverse slope of the deck, taking into consideration the weight of the operator and finishing mechanism.

Dry runs should be made in accordance with the procedure at the end of this section to assure proper operation and slab thickness. Links to setup demonstration videos are also included in the procedure. Pour direction and finishing direction can have drastic effects on the finish, and should be checked during the dry run and discussed at the Pre-Pour meeting. Ideally, the dry run should be performed before the Pre-Pour Meeting and the results discussed at the meeting.

B. Longitudinal Screed

Longitudinal Screeds are rarely used due to limited span length capability and the ease of grading transverse screeds. If a longitudinal screed is proposed to be used, contact the Area Construction Engineer to determine if it is an acceptable application and for assistance with reviewing the setup.

The grade for the screed shall be computed accurately and set in the screed with an engineer’s level or a string line. The shape of the screed should end up reflecting the vertical alignment of the road where the screed is set. Computation of screed grades is somewhat complicated for continuous spans when a longitudinal screed is used. Procedures included in the Engineering Control Section of this Manual are recommended.

When using longitudinal screeds: the first interior bay should be loaded with concrete before loading the overhang. This procedure will minimize unequal beam deflections. As soon as the first overhang has been loaded and the deck concrete has been screeded beyond the second beam, the overhang shall be checked for grade. For full pour simple spans, the grade should be checked with an Engineer's level. For simple spans with multiple pours and continuous spans, the overhangs should be checked with a “preacher.” Although the “preacher” does not assure exact final grades, it does assure smooth lines on the overhang. Details for constructing a “preacher” are included in the aforementioned procedure for grading overhang forms, headers, etc. If form adjustment is necessary, it should be made immediately. The other overhang should be checked as soon as it is loaded.

Dry Run Procedure for Transverse Screeds

- Screed Rails can be set initially by measuring up a constant distance from the overhang form or the top of the side form, but this is only preliminary. Final adjustments must be made prior to the dry run.

For more detailed discussion of screed setup see Chapter 4 of the Structures II (CON 815) Manual and view the Transverse Screed Setup videos on

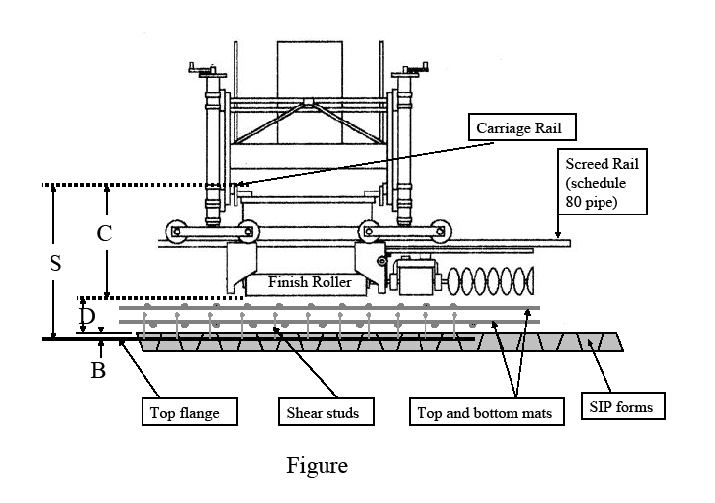

YouTube Construction Unit Training playlist. Before beginning, at all four corners of the screed, the distance from the screed rail up to the carriage rail should be the same and the carriage rail should be straightened (Video 1), the rollers should be aligned (Video 2), and if the bridge is in a crown section, crown can be adjusted into the truss at this point (Video 3).

-

The screed should be pulled to the zero buildup location of one exterior girders. The distance from the buildup to the bottom edge of the front of the drums should be measured. Both legs on this side of the screed should be adjusted identically until the distance measured is equal to the deck thickness plus the buildup. This step should be repeated for the other exterior girder. After this, the screed is set to grade (Video 4).

-

Begin on one of the exterior girders. At each 20th point (or 40th or 60th point on longer spans) use the stick constructed in

Video 4 to measure up from the top of the girder to the carriage rail. The carriage should be located as close to the exterior girder line you chose as possible and still allow for easy measurement. This measurement should equal the calculated buildup.

-

If the buildup is greater than the calculated buildup, the screed rail should be lowered until the plan buildup is achieved. Conversely, if the buildup is less than the plan thickness, the screed rail should be raised until the calculated buildup is achieved. The screed rail is adjusted by turning the nuts located between the top of the side form and the screed rail saddle.

-

Steps 4-5 should be repeated for each twentieth point on the exterior girders before checking the interior girders. Any errors found on the interior girders at that point should be minor variations due to incorrect pan elevations or the arithmetic difference in the plan dead load deflection of the particular interior girder and that of the exterior girder.

-

Verify the plan deck thickness from the deck pans to the finish roller and the plan cover over the top mat of rebar. The tolerance for deck thickness and rebar cover should be +/- 1/8th inch. The thickness and cover should be checked at least every other 20th point (or 40th or 60th point) at the center of the concrete deck panel or SIP form.