The importance of proper bonding at the asphalt concrete (AC) layer interface cannot be overemphasized when discussing the performance of AC pavements. The primary objective of this research is to develop a set of test procedure and acceptance criterion that can be used in a tack coat quality control (QC) program to mitigate debonding in asphalt pavements.

This study covers the effects of tack coat application rate, AC surface conditions (milled and unmilled), confining pressure, strain rate, and temperature on interface shear strength (ISS) of double-layered AC specimens.

Five types of tack coats were used in this study, including CRS-2 (Source 1), CRS-2 (Source 2), CRS-1h, NTCRS-1hM, and Ultrafuse. The experimental design was to measure the binder bond strength (BBS) of each of these five tack coats and the interface shear strength (ISS) of double-layered AC specimens that were fabricated using a warm mix designated as RS9.5C with 20% AP in a gyratory compactor.

The ISS predictive model was developed as a function of confining pressure, temperature, and shear strain rate. The three-dimensional pavement analysis program, FlexPAVETM version 1.1 was used to determine pavement responses. The shear ratio was defined as the ratio of the shear stress calculated from FlexPAVE to the shear strength along the interface. The maximum shear ratio (MSR) was used to define the debonding potential of a pavement. The normal stress to the interface and the shear strain rate determined from FlexPAVE were input to the ISS predictive model to predict the shear strength at various locations in a pavement structure. FlexPAVE simulations under numerous field conditions were also used to develop a universal relationship between the ISS and BBS that is independent of the tack coat type. The ISS-BBS relationship led to the development of a predictive model for the MSR as a function of BBS and depth of the interface. Assuming that all the tack coats considered in the study are acceptable, the MSR-BBS relationship resulted in the BBS threshold value of 75 kPa at 50°C. However, if the layer above the tack coat is an open-graded friction course (OGFC), the cut-off is maintained at 750 kPa.

![]()

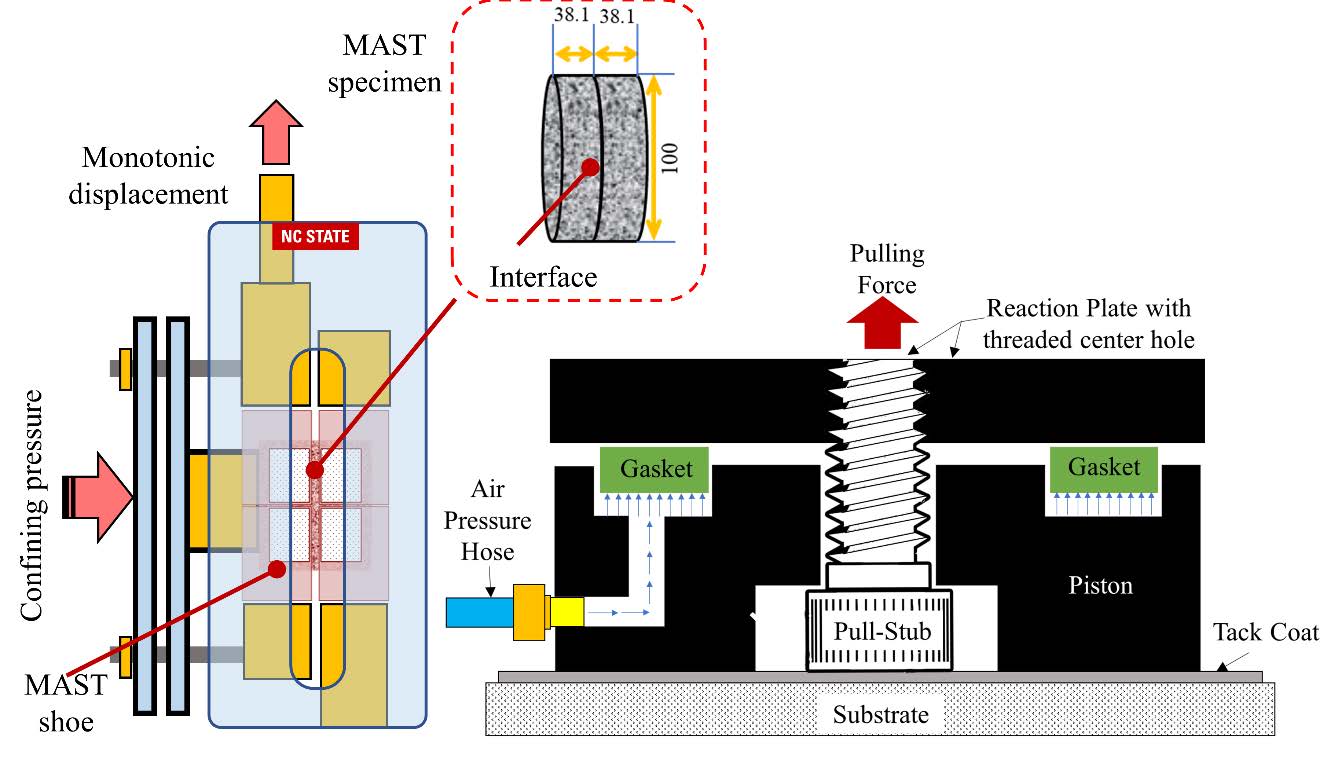

Schematic illustrations for MAST test setup and

PATTI test setup

The experimental work verified that the time-temperature superposition is valid for the ISS and BBS. The ISS results showed that the confining pressure, temperature and strain rate have a significant effect on ISS whereas the tack coat application rate, tack coat type, and surface condition with laboratory-fabricated grooves with different angles do not have a significant effect on ISS.

However, it must be noted that the monotonic loading used in measuring the ISS and the laboratory-fabricated grooves may not represent the field conditions properly. Additional research with the shear fatigue test and the milled surface in the field is recommended for future study.