Traditional asphalt mixture design in North

Carolina, which is based primarily on volumetric properties and rutting

performance, does not sufficiently ensure long-term durability across diverse

pavement conditions. While the Asphalt Pavement Analyzer (APA) has been used to

mitigate surface rutting, it lacks the capability to address durability,

leaving a critical gap in achieving balanced performance.

This research

addresses that gap by evaluating and proposing a framework for integrating both

cracking and rutting performance tests into the mix design and quality assurance

processes—a methodology known as Balanced Mix Design (BMD). A comprehensive

experimental program was conducted on 14 surface mixtures obtained across North

Carolina. Laboratory testing included Indirect Tension Cracking Test (IDT-CT)

for cracking resistance, APA for rutting, Indirect Tensile Strength at High

Temperature (IDT-HT), Cyclic Fatigue (CF), Dynamic Modulus (DM), and Stress

Sweep Rutting (SSR). Performance predictions were made using FlexPAVE™ to link

laboratory results with anticipated field performance.

The study found

substantial variability in both rutting and cracking resistance among mixtures,

with performance strongly tied to plant source. Cracking resistance, in

particular, showed complicated relationships across tests, with no single test

perfectly predicting the simulated field performance. Nonetheless, the IDT-CT

test demonstrated promise as a practical and efficient measure of cracking

resistance, with a preliminary threshold value of 14 suggested for North

Carolina surface mixtures. The IDT-HT test emerged as a cost-effective and

efficient rutting evaluation tool.

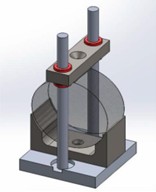

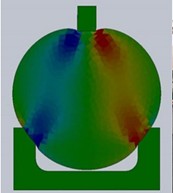

IDEAL-RT Test apparatus and stresses

Preliminary minimum strength thresholds of

approximately 150 kPa, 180 kPa, and 215 kPa were identified for RS9.5B, RS9.5C,

and RS9.5D mixtures, respectively. Importantly, performance test results

aligned well with simulated rutting but were less predictive of cracking

outcomes, reinforcing the need for multiple tests to ensure a comprehensive

understanding of mixture behavior. Survey responses from both contractors and NCDOT

personnel confirmed that current APA-based approvals rarely lead to test

failures or quality concerns, suggesting that the opportunity may exist to adjust

mixtures to improve IDT-CT results while producing mixtures that meet existing

APA thresholds.

While concerns regarding training, equipment, and lab capacity

were noted, personnel expressed a willingness to adopt a phased implementation

strategy. This study concludes with recommendations to incorporate IDT-CT and

IDT-HT tests into North Carolina’s asphalt mix design and QA framework. Doing

so may provide a more balanced assessment of mixture performance, reduce

variability in field outcomes, and extend pavement life.

Future work should

include refinement of performance thresholds and a pilot implementation to

validate specification updates in real-world conditions.