As funds to construct, maintain, and preserve our highway infrastructure become increasingly stretched, it is imperative that the criteria for selection of concrete mixtures and acceptance of placed concrete reliably ensure durability. Over the past several decades, research has led to new understanding of deterioration mechanisms, advancements in concrete mixture design, and better field and laboratory tests to aid in QA/QC. AASHTO PP 84, “Standard Practice for developing Performance Engineered Concrete Mixtures” provides guidance to agencies aiming to improve the durability, economy, and sustainability of their infrastructure using both prescriptive and performance specification provisions and emerging technologies. Although developed for pavement concrete mixtures, the approach outlined in AASHTO PP 84 can be extended to include pecifications for performance-engineered concrete mixtures utilized for other infrastructure (bridges, lower grade uses, etc.) as well.

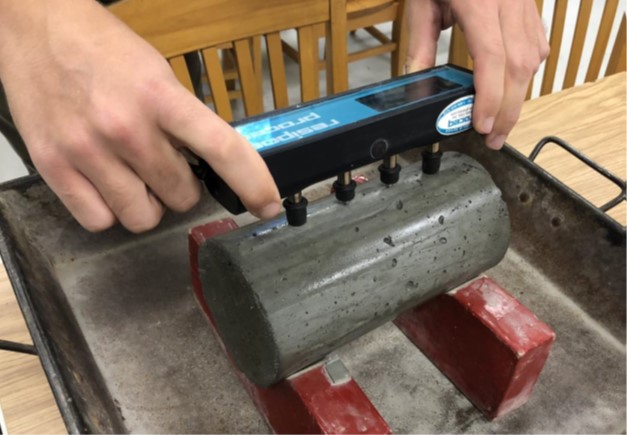

The scope of work in this project supports an initial effort to move towards a specification for performance-engineered concrete mixtures by 1) utilizing existing data to identify areas in need of improvement, 2) targeting the establishment of performance-related criteria using several PEM QA/QC tests and approaches of interest to NCDOT, and 3) providing a “roadmap,” outlining recommended tasks towards implementation of performance measures, performance goals, and QA/QC protocol in other areas. Existing data from previous concrete research projects for NCDOT were leveraged with new, targeted data to efficiently develop proposed specifications for three areas of interest to improve durability of future concrete infrastructure: surface resistivity, early age strength for opening to traffic, and shrinkage. Guidance for other performance and prescriptive (including water-cementitious ratio and paste content) is also presented for consideration. Suggested specification provisions developed as part of this project are suitable for use by NCDOT on several upcoming projects targeted as pilot projects for PEM research.

Additional study to evaluate the performance of concrete mixtures that include the combination of both fly ash and portland limestone cement (PLC) was also performed. Findings of this work align with previous findings by the research team, indicating significant durability performance benefits in mixtures that contain the two materials. Performance improvements were particularly noted at the current allowable fly ash replacement (30%), which has been increased in recent years. The enhanced durability, sustainability and economy of these mixtures provides additional justification for use of PLC and higher fly ash contents. Findings of this study should allow NCDOT to specify and use of more durable, sustainable concrete mixtures in North Carolina highway infrastructure. Ultimately, paired with other efforts aligned with the national PEM initiative, findings this project should result in cost savings associated with construction costs, QA/QC costs, reduced maintenance costs, and extended life of concrete pavements and bridges.