The Emulsion Application Rate (EAR) is critical to the performance of

both tack coats and chip seals. When emulsion is applied to an aged flexible

pavement, a portion of the applied emulsion will be absorbed by the existing

pavement. To compensate, the current practice is to adjust the required target

EAR used in the construction based on visual inspection of the existing

pavement surface, which is subjective.

The objectives of this project are to:

(1) determine the pavement emulsion absorption rate as a function of surface

characteristics and (2) develop guidelines for the adjustment of the target EAR

to account for emulsion absorption based on quantitative measurement of the

existing pavement surface characteristics.

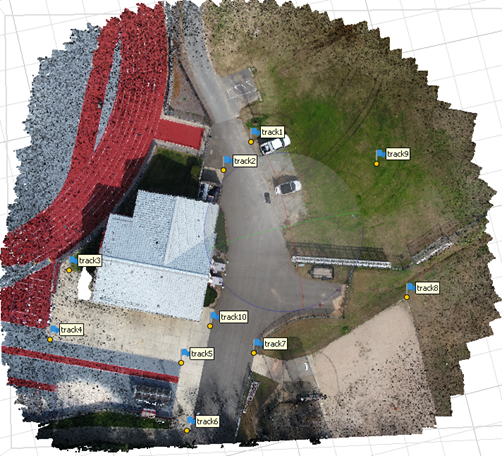

Tack Lifter field experiments conducted on 13

pavements indicate that the absorbed EAR vary considerably depending on the

existing pavement surface conditions.

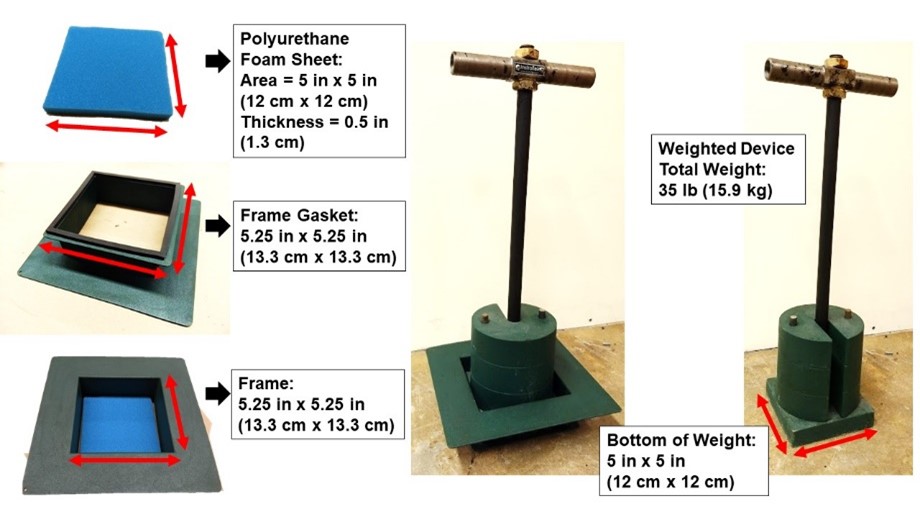

CR 400 Colorimeter Tack Lifter Components

Statistical analysis of the field

measurements acquired in this study indicate that the application (i.e., chip

seal versus tack coat) and mean texture depth affect the resultant pavement

emulsion absorption rate. A linear regression model was calibrated to predict

the pavement emulsion absorption rate as a function of mean texture depth and

application that yielded moderate prediction accuracy (R2 = 0.56).

The moderate prediction capability indicates that other factors that were not

captured by the application type and texture influence the emulsion absorption

capacity of pavements but allows for an approximation of the absorbed EAR in

cases where project-specific Tack Lifter testing cannot be conducted.

Tack

Lifter experiments conducted on field cores in the laboratory indicate that

Colorimeter measurements of hue are moderately correlated to the pavement

emulsion absorption rate (R2 = 0.42), which merits further

investigation using field experiments in the future. Field core measurements of

emulsion absorption rates indicated differences from field measurements of

emulsion absorption rates with respect to sensitivity to the mean texture depth

and mean values in tack coat applications. This could be due to differences in application

procedures in the field versus the lab. Also, field measurements were made in the wheel path

whereas field cores were extracted elsewhere.