Asphalt overlays often fail prematurely by allowing the propagation of existing cracks over the overlay surface, thereby forming reflective cracks. Among the many available interlayer reinforcement technologies, geosynthetic products are gaining popularity for mitigating reflective cracking. The main goal of this research effort is to ensure that North Carolina Department of Transportation engineers can choose the appropriate geosynthetic pavement interlayer product for a specific application based on performance data. The negative side effect of geosynthetic applications for surface paving is aggravation of the debonding distress. Hence, another objective is to develop a tack coat selection criterion for a specific geosynthetic type that safeguards against debonding failure.

The scope of the test plan includes five geosynthetic products designated as paving composite #1 (PC#1), paving composite #2 (PC#2), paving grid (PaG), paving mat (PM), and paving fabric (PF). In this study, geosynthetic-reinforced and unreinforced specimens were tested using four-point notched beam fatigue test equipment together with the digital image correlation (DIC) technique and a Modified Asphalt Shear Tester to measure the specimens' crack resistance capacity and interface shear strength, respectively. The double-layered asphalt concrete specimens were fabricated in gyratory and slab compactors using a hot mix designated as RS9.5C with 40% reclaimed asphalt pavement.

The geosynthetic product was sandwiched between the asphalt layers with a tack coat (PG 64-22) applied at the rate recommended by the geosynthetic product's manufacturer. Binder bond strength (BBS) tests were performed on the PG 64-22 binder. The DIC data were analyzed to determine the Von Mises strain, which in turn was used to determine the failure mode of the geosynthetic-reinforced asphalt beams. The DIC contours revealed that the failure mode could be classified into either vertical cracking or debonding and that each of these two failure modes depends on the geosynthetic product type, tack coat application rate, and strain level. Sufficient bond strength is needed to minimize debonding at the interface and is an important factor to mitigate vertical reflective cracking as well.

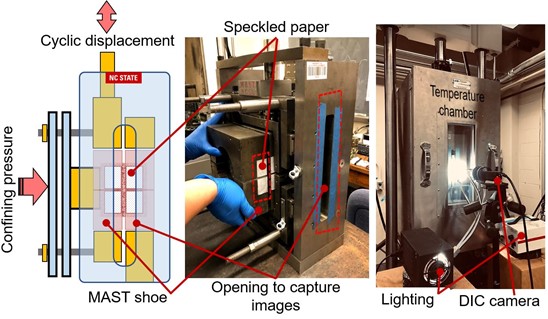

MAST test set-up: (a) schematic diagram, (b)

loading MAST shoes into loading jig, and (c) test set-up with DIC system

The three-dimensional pavement analysis program, FlexPAVE™ v. 1.1, and EverStressFE v 1.0 were used to determine the pavement responses. The pavement response analysis for numerous layer modulus and thickness combinations led to a predictive equation for interface tensile strain (et-overlay). The predictive et-overlay equation is a function of the surface curvature index, base damage index, base curvature index, and overlay thickness. A geosynthetic product selection table was developed based on the expected improvement factor and failure mode that correspond to the field et-overlay. Subsequently, a tack coat criterion for each geosynthetic product was developed based on the maximum shear ratio and BBS relationship. The BBS threshold values for PC#1, PC#2, PaG, PM, and PF are 280 kPa, 860 kPa, 455 kPa, 860 kPa, and 280 kPa, respectively.

The results of this research effort are the guidelines developed for geosynthetic interlayer product selection and for tack coat selection. Populating more laboratory and field data is highly encouraged and will help to reinforce and improve the findings from this study and assist in the implementation of the developed guidelines in practice.