The objectives of this project are to: 1)

develop recommendations for extender and recycling agent product approval and

dosage selection; and 2) identify appropriate aging procedure(s) to simulate

long-term oxidative aging coupled with test methods and parameters to

characterize the cracking resistance of asphalt binders.

Three NCDOT approved

surface asphalt mixtures were evaluated in this study, including a reclaimed

asphalt pavement (RAP) mixture, recycled asphalt shingle (RAS) mixture, and

RAP/RAS mixture. Three extenders and two recycling agents (RAs) were evaluated.

The extenders were blended with PG 58-28 virgin binder whereas the RAs were blended

with PG 64-22 virgin binder. Blends of recycled binder, virgin binder, and a RA

or extender were prepared that achieved similar high-temperature AASHTO M 320

performance-graded properties to virgin PG 64-22 binders in North Carolina.

These blends exhibit distinct but also potentially superior low- and

intermediate-temperature characteristics compared to PG 64-22 virgin binders on

the basis of performance-grade properties and several other rheological

measures of durability.

In contrast, NCDOT’s current practice to use a PG 58-28

virgin binder in high recycled binder replacement mixtures resulted in similar

intermediate- and low-temperature performance-graded properties to PG 64-22

virgin binders in North Carolina for the materials evaluated. However, the

current practice resulted in high-temperature performance-graded properties

that were distinct from PG 64-22 virgin binders.

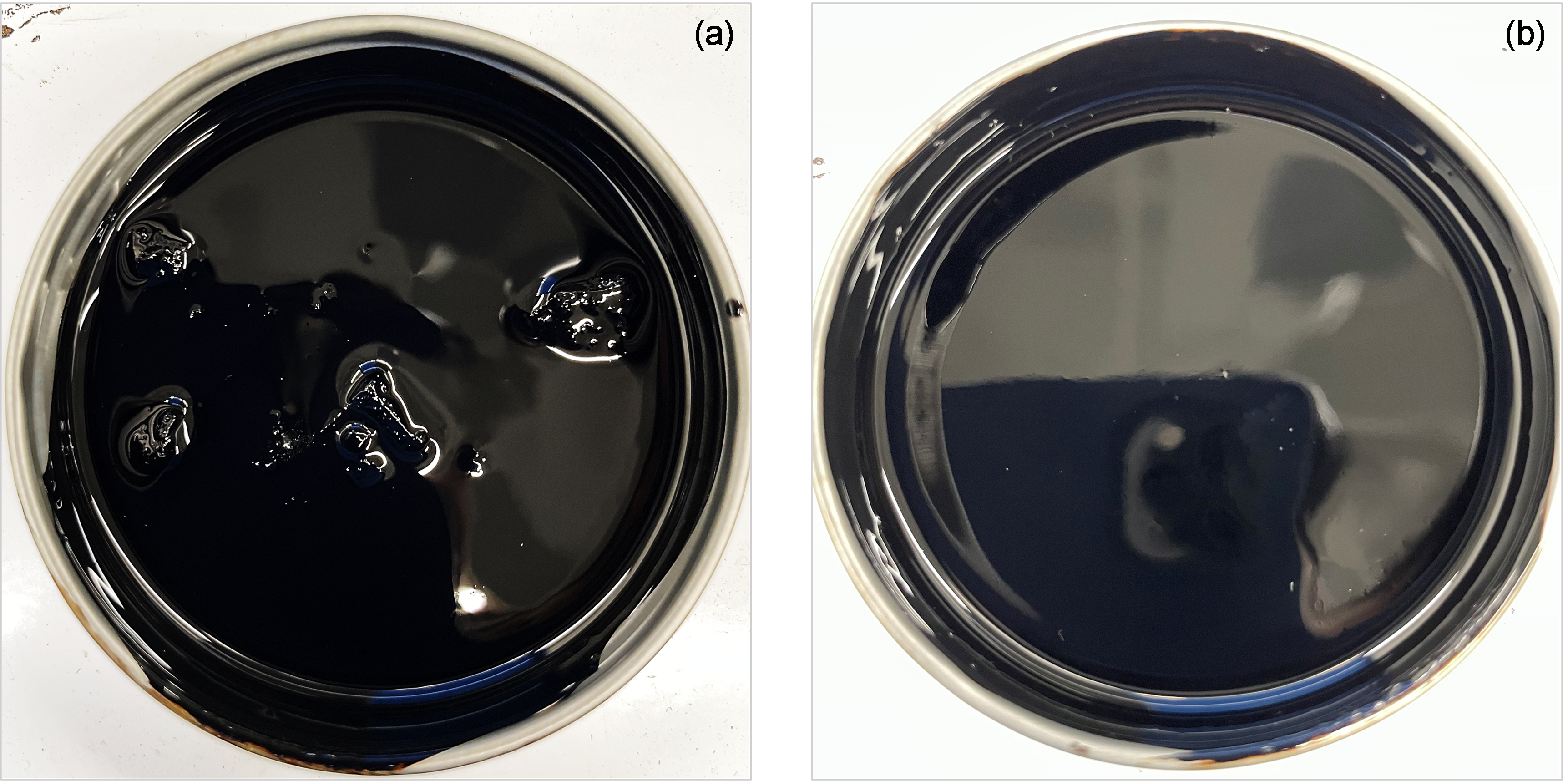

(a) RAS lumps visible after blending in original

state (b) No RAS lumps visible after RTFO aging

The collective results

highlight that neither the current practice to use a PG 58-28 virgin binder in

high recycled binder replacement mixtures or the use of an extender or RA can

fully restore rheological properties of recycled binder blends to those of PG

64-22 virgin binders. The inability of additives of fully restore rheological

properties was also identified in some cases through inferior measures of the

balance between stiffness and relaxation characteristics, including ΔTc

and R values.

Long-term aged asphalt mixtures prepared according to the current

practice and with the additives displayed similar dynamic modulus and fatigue

cracking resistance, which may have been a consequence of the harsh

laboratory-induced age level. Short-term aged mixtures prepared according to

the current practice and with the additives met recommended Hamburg Wheel Track

Test rutting limits. The additives were found to be ineffective at increasing

recycled binder contribution in asphalt mixtures.

Based on the collective

results and findings, an additive dosage selection and product approval process

was proposed. In addition, the results of this study suggest that the

consideration of alternative rheological measures of binder durability that are

readily obtained from standard Performance Graded (PG) test results may aid in

screening of asphalt binders for cracking resistance