This report summarizes the findings of a study

evaluating the variability of Reclaimed Asphalt Pavement (RAP) and Recycled

Asphalt Shingles (RAS) stockpiles across North Carolina and the corresponding

performance of plant-produced asphalt mixtures. The goal of this study was to

inform improved specifications for recycled materials in asphalt mixtures by

assessing how processing and stockpiling practices influence material

consistency and mixture performance.

Seven asphalt plants operated by five

contractors were selected across the coastal and piedmont regions of the state.

Over approximately 1.5 years, researchers conducted operational reviews and repeatedly

collected samples of plant-produced mixtures, RAP, RAS, and virgin binder.

These materials underwent laboratory testing to evaluate binder content,

aggregate gradation, specific gravity, recycled binder availability (RBA), and

recovered binder performance grade (PG). Asphalt mixture performance was

assessed using indirect tensile cracking test (IDT-CT) and asphalt pavement

analyzer rutting (APA) test. RAP binder contents ranged from 4.3% to 5.4%.

While some plants maintained consistent RAP properties, one plant which

performed monthly in-house jaw crushing, exhibited greater variability in

asphalt content. Plants relying on outsourced impact crushing with less

frequent replenishment showed more stable asphalt content results.

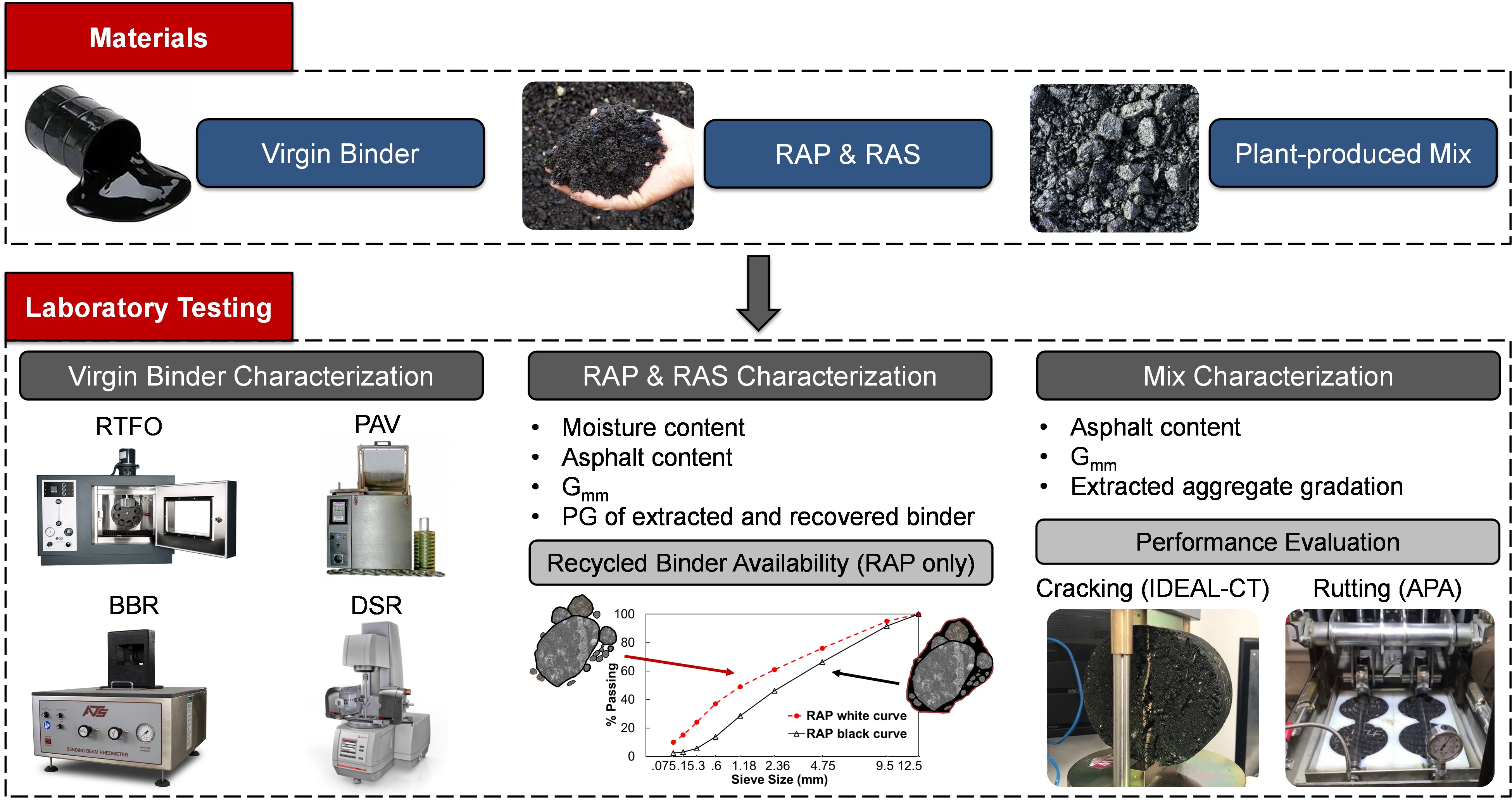

Summary of the tests used to evaluate the

materials

A

probabilistic analysis of NCDOT’s recycled binder replacement percentage (RBR%)

limits showed that lowering the limit for PG 64-22 mixtures from 30% to 20%

increased the probability of meeting AASHTO M 320 intermediate- and

low-temperature PG requirements from 75% to 95%. This compliance could be

maintained at higher RBR% levels using PG 58-28 binder. IDT-CT results were generally

consistent within a given plant over time but varied across plants.

Rutting

performance also varied but all mixtures fell well below NCDOT’s APA limits. IDT-CT

results were most strongly correlated with VMA, asphalt content, and binder

properties, while APA results were linked to aggregate gradation.

The findings

support tighter controls on mixture volumetrics and gradation and highlight the

need to incorporate cracking performance tests into mixture design and potentially

quality assurance to ensure consistent performance when using recycled

materials.