The

Proof Rolling Daily Report (M&T Form 507) documents proof rolling operations and serves as a pay record that supports final payment for proof rolling. Since the form serves as a source document for payment, proof rolling need not be recorded in a pay record book. M&T Form 507

is located in SharePoint for the contract the work is being performed on in the Reports section. For training on how to fill out the Proof Rolling Report please go to the SharePoint Help Guide for Proof Rolling.

The report should be completed daily for each proof rolling operation. It should be Approved by the Resident Engineer or Assistant Resident Engineer after being reviewed to indicate concurrence with the contents and to signify acceptance of the report as a source document for payment purposes. The Inspector should not Approve the report in lieu of the Resident Engineer reviewing and Approving the report.

The Proof Rolling Daily Report should contain the following information:

-

PRR Date: The date the Proof Rolling work is performed. A separate report must be completed for each crew, each day, and/or each work order.

-

PRR Report No.: The number of the report. Each WBS Number should have its own sequentially numbered set of reports.

-

Reroll?: Click on if this is a reroll section.

-

Roller Make: The make of roller used for proof rolling, including the model number.

-

Tire Size and No. Plies: The size of the tires and the number of plies the tires have, such as 20 x 28 (36 ply). All tires should be the same manufacturer and size.

-

Weight (Tons Gross): This should be the gross weight of the proof roller in tons.

-

Air Pressure (Checked on a daily basis): This is the air pressure of each tire, checked on a daily basis. Incorrect tire air pressure can cause the weight of the proof roller to be unequally distributed during the proof rolling process. This may prevent the proof roller from detecting unstable areas. The recommended tire pressure is

68-72 psi.

-

Start Time: The Inspector should record the time the contractor started work per a 24-hour clock format therefor 6:00am would be entered as 06:00 or 0600 (likewise 2:30pm would be entered as 14:30 or 1430). The Contractor is paid for all initial proof rolling. In the event of failure due to the Contractor's negligence or weather, the Contractor is required to perform corrective measures and proof roll the failed area at no cost to the Department. Proof rolling hours for which payment is not to be made as provided by

Section 260 of the Specifications will be kept separate from

proof rolling hours for which payment is to be made (see

Failures below).

-

Stop Time: The Inspector should record the time Proof Rolling Stopped and should be entered per a 24-hour clock format (16:00 or 1600).

-

Roll From: Inspector should record the station where the Proof Rolling started in Station Format (12+50). Areas that have passed proof rolling requirements of the contract should be recorded by specific station number in this section of the form along with the number of coverages performed. Proof rolling is typically performed on all areas of a project. Special emphasis should be placed on grade points, undercuts, or other questionable areas.

-

Roll To: Inspector should record the station where the Proof Rolling Stopped in Station Format (17+85).

-

# Failures: The number of areas that failed proof rolling should be recorded by specific station number in this section of the form. Each failure should be noted by identifiable asterisks. Sufficient information to document the failure should be provided as listed below:

-

Failure Location: areas that failed proof rolling should be recorded by specific station number in this section of the form. Each failure should be noted by identifiable asterisks.

-

Failure Cause: Document the reason the subgrade failed the proof rolling and any conditions at the specific location.

-

Correction Details: Document what corrective measures were performed by the Contractor to correct the section. Do not allow the Contractor to wait several days and proof roll again without performing corrective measures. A second coverage on a previous failure area should be noted as such. A definition of coverage is shown at the bottom of the form.

-

Inspector's Comments: Any remarks regarding payment for work and the Contractor’s performance should be recorded in this section of the report for each area.

-

Title: Optional title for this report (the default is Proof Roll). An example title might be “ PR Report #141 – Section 2 (Y9)"

Each report should be saved and approved in Share Point for all Department staff to be able to review as a source document...

Proof rolling reports should be numbered consecutively, except when failures occur. If a section that has been proof rolled fails, the next report that covers that section should have a letter designation that continues progressively with each report until it passes. For example, if a section on report 1 fails, that area should be shown on report 1A the next time it is rolled. If it does not pass on that report, it will next be shown on report 1B. This will better enable project personnel to ensure all failing areas are re-rolled.

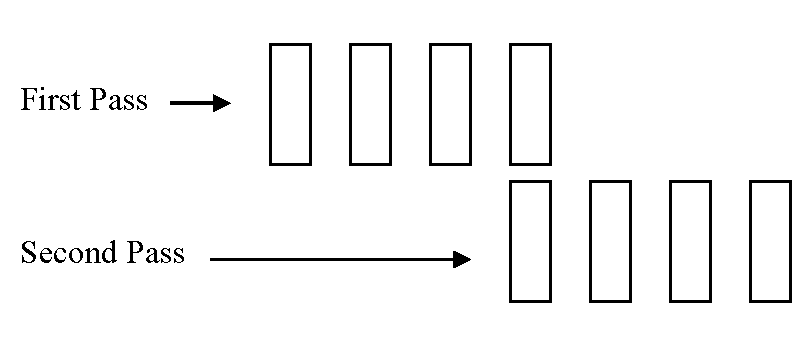

The correct proof rolling procedure is accomplished by operating the proof roller in the following manner: