FINAL PROJECT INSPECTION

PROCEDURES FOR SCHEDULING AND CONDUCTING FINAL PROJECT INSPECTIONS

-

The Contractor and Resident Engineer should communicate and discuss punch list items throughout the life of the project. “Catch it as you go. Do a “final” everyday.”

- The Contractor should make a request to the Resident Engineer for Final Inspection within

2 – 3 weeks of the project or portions, as provided in

Article 105-17, being complete.

- The Division (Resident Engineer) will schedule a Final Inspection Date with the Area Construction Engineer and the Division Construction Engineer.

- Once the Final Inspection Date has been established, all stakeholders that the Division desires to participate in the Final Inspection should be notified to perform their evaluation of the project either on or prior to the Final Inspection Date. County Maintenance Engineers, Bridge Maintenance Engineers and Roadside Environmental Engineers may be requested to evaluate the project. Any recommendations should be provided to the Resident Engineer for inclusion in the Final Punch List.

- Prior to the Final Inspection Date, the Contractor should, at minimum, thoroughly evaluate their project for the Common Final Punch List Items (attached) to ensure all work is satisfactorily completed.

- On the Final Inspection Date, a Final Punch List will be generated by the Resident Engineer, Division Construction Engineer, and Area Construction Engineer from the evaluation of the project. Recommendations for other stakeholders will be added to the Final Punch List. The Resident Engineer should provide the Contractor with a completed list once all parties have reviewed the project.

- Once the Contractor has satisfactorily completed all work detailed on the Final Punch List, the Resident Engineer will notify the Area Construction Engineer and the project will be accepted.

- The Area Construction Engineer will complete the Engineer Acceptance Report detailing the final acceptance of the project and a letter will be provided from the Construction Unit to the Division and Contractor accepting the project. On Division Contracts, the Resident Engineer will fill out the Engineer Acceptance Report and the Division will generate the final acceptance letter.

FINAL INSPECTION COMMON PUNCH LIST ITEMS

Asphalt Pavement

- Good ride quality

- Longitudinal joints in correct location (not under wheel path)

- Transverse and longitudinal joint are smooth

- No fuel spills on asphalt and shoulders

- No segregation

- Correct cross slope

- No standing water or water stains

- Valves and manholes adjusted to proper height

- Driveways (tie-in, widths)

Concrete Pavement

Pavement Marking

- Stop bars/cross walks/ arrows/ symbols per plan or specification

- Thermoplastic/paint workmanship (straight, weeps in thermoplastic, right color, width, excess marking removed, not placed over mud or dirt, proper thickness)

- Retroflectivity of thermoplastic/paint

Signs

- Installed per plan

- Correct orientation

- Cleaned

- Metals Engineer list completed

- Overhead lighting inspection by Division

- Overhead sign anchor bolts/nuts secured

Grading

- No standing water in ditches, yard, etc.

- Slopes graded to correct cross slope ( to include median ditches)

- Project properly vegetated or seeded (no weak or bare areas)

- All washes repaired and seeded

- No more than one inch drop-off at edge of pavement (EP)

- Mowing and topdressing has been performed

- Erosion control measures removed unless otherwise directed

Guardrail/Guiderail/Barrier

- Cross slope per standard drawing

- Clear roadside recovery zone

- No tack on rail end units or barrier

- Workmanship (correct height, bolts on correct side and tight, tension on wire, delineators, good finish on barrier, clean)

Drainage

- Drainage structures cleaned out

- Pipes are flush with inside wall of box/inverts poured

- Pipes sealed properly

- Frames and boxes grouted where weep was left during grading

- Correct type of grate

- Grate does not rock

- Steps installed

- Pipes clean

- Not missing expansion joint material between box and apron, expansion joint sealed

- Aprons are not damaged

- Pipe near subgrade level inspected for crush or cracked sections

Miscellaneous Concrete

- Sidewalk (good finish, joint spacing, no cracks, writing, or footprints)

- Curb and gutter (good finish, joint spacing, no standing water, cracks replaced or sawed and sealed, joints sealed)

- Handicap ramps in correct location , installed correctly

Fence

- No damaged areas

- Tree/ debris removed

Signals

- Inspected by Division Traffic Services

- No stone in bottom of pullboxes

- Signal head clearance

Overhead Lighting

Borrow/Waste

- Pits reviewed with property owners

- Plan matches actual final condition of pit

- All erosion control measures removed unless otherwise directed

- Pit has been seeded with stand of grass established

- Graded to drain

- All washes repaired and seeded

General

- Rocks and asphalt/concrete chunks removed

- All stockpile areas cleaned and seeded and mulched

- Trash picked up

- Mail boxes adjusted/relocated

Structures

- Asphalt not placed in bridge wing walls

- Evazote Joint Repairs – Inspect joints for spalling, excess glue on evazote seal, splitting of seal at splice, properly installed evazote that is firmly bonded to joint opening, damage to coating on armored angles, weep holes in angle should not have voids, sound the metal angles for voids

- Water test expansion joint seals as required in the project special provisions

- Sound

50% of stay in place metal decking – additional sound if problems are found

- Clean concrete slurry from deck and barrier rail after grooving deck

- Clean tack, oil, dirt, and debris from deck

- Inspect Bearing position in relation to anchor bolts to ensure sufficient space for future movement. Make adjustments as needed.

- Remove concrete slurry from girders

- Repair damaged paint on girders and diaphragms with same paint used by the fabricator

- Painting welds on sole plates

- Painting ends of tie rods (concrete girders) with NCDOT approved bush on zinc rich paint

- Recess and seal expansion joint material between slope protection / end bents / wings

- Recess and properly patch exposed form ties

- Clean aluminum handrail and tighten all bolted connections

- Check bolted endblock connection on aluminum handrail to ensure a bolt that can be removed and reinstalled

- Check guardrail anchor system – patch spalling from drilling operation, tighten nuts, make sure proper number of posts (even field drilling the rail to install end post near at backwall

- Install barrier delineators

- Clean tops of caps and epoxy caps as required by plans – check and repair damaged epoxy as needed

- Properly install PVC pipe, nuts, washers, and burr threads on anchor bolts

- Remove all forming materials from end bent joints

- Remove from fins from bottom of interior bent caps, bottom of overhangs, and other chamfered edges

- Patch overhang jack holes

- Point and patch substructure as needed (deep air bubbles larger than a dime). Make sure final surface finish is uniform – avoid spotty looking patchwork

- Review end bent caps and around perimeter of slope protection for scour holes – fill with flowable fill as needed

- Trim top of permanent casing on drill shaft to elevation of concrete and remove column forming support aids

This list is not all inclusive of the items needed for final acceptance and should serve as a list of common items needing attention prior to the Department performing a final inspection.

ADVANCE NOTICE OF NEW STRUCTURE COMPLETION

The Structures Management Unit (SMU) is responsible for the inspection, load capacity analysis, inventory, and administration of maintenance policies and procedures for structures on the State Highway System, which includes but is not limited to bridges, reinforced box culverts, and pipe groupings larger than 20' in width. The Federal Highway Administration (FHWA) has established National Bridge Inspection Standards to help create uniformity nationwide and to ensure both older and new bridge types are properly monitored. FHWA requires the inspection of new structures within 30 days of opening the structure to traffic. The submittal of the Advance Notice of New Structure Completion form will notify SMU that a bridge is nearing completion and will need to be inspected. SMU prefers that the inspection be performed prior to opening the structure to traffic.

The Advance Notice of New Structure Completion form can be found in the individual projects Construction Team Site within each Division. The critical steps in the process are as follows:

-

The Resident Engineer will fill out and complete the online Advance Notice of New Structure Completion form

-

The Resident Engineer will submit an email with attached web link of the completed form to the Division Construction Engineer, Area Construction Engineer, SMU personnel listed on the form, and the State Signing and Delineation Engineer if overhead signs are included.

-

Complete the form approximately 4 weeks prior to completion of the structure and use an estimated completion date.

-

If the anticipated date of opening to traffic changes, a revised form can be sent.

NOTICE OF VERTICAL CLEARANCE CHANGE

The Structures Management Unit (SMU) is required to maintain a database of the vertical clearances on all roadways. The database is used to evaluate proposed routes for oversized loads. To assist in making sure SMU has the most current information; Resident Engineers should report any changes (increases and decreases) in overhead clearances. Reported changes include vertical clearances for new bridges and sign structures, new vertical clearances due to construction or resurfacing under structures and removal of existing structures.

The Notice of Vertical Clearance Change form can be found in the individual projects Construction Team Site within each Division. The critical steps in the process are as follows:

-

The Resident Engineer will fill out and complete the online Notice of Vertical Clearance Change form

-

The Resident Engineer will submit an email with attached web link of the completed form to the Division Construction Engineer, Area Construction Engineer, Oversize/Overweight Permits, and Structures Management.

-

The report should be completed and sent immediately upon changing of the vertical clearance.

-

For divided multilane facilities, provide minimum clearance values for each direction of travel; Also list collector/distributor lanes separately

-

Report values in English Units and round down to nearest inch.

-

Provide as much information as possible to identify the structure location.

DECK AND RAIL ACCEPTANCE

Article 105-7 states that bridge decks and rails that have been constructed or rehabilitated and are opened to public traffic can be accepted prior to acceptance of the project. Prior to opening the bridge(s) to traffic, an inspection shall be performed by the Area Construction Engineer and all punchlist items completed. The Area Construction Engineer shall be notified immediately when traffic is placed on the bridge. The Engineer Acceptance Report will be filled out and sent to the appropriate personnel listed on the form documenting the acceptance of the deck and rail. The Deck and Rail acceptance should be completed within 72 hours of opening the road to traffic. The

Deck and Rail Acceptance is required on all bridges, whether completed prior to final acceptance of the project, or in conjunction with the final acceptance. On DivisionLet Contracts and Locally Administered Projects (LAP), the Resident Engineer shall fill out the Engineer Acceptance Report for Deck and Rail acceptance.

FHWA requires the NBIS inspection of new structures within 30 days of opening the structure to traffic. The Resident Engineer should have already sent in the Advance Notice of New Structure Completion form to SMU around 4 weeks prior to completion of the bridge. The Deck and Rail Acceptance is the Contractual Acceptance of the bridge, and is the date used by FHWA in establishing the 30 day inspection requirement. Therefore, it is critical that this form be sent within the 72 hour time frame.

Additionally, this contractual acceptance of the deck and rail triggers the beginning of the 12 Month Guarantee Provision for the bridge. This is tracked in the Project Guarantee tab under Review Contract Details in HiCAMS.

The Deck and Rail Acceptance form shall also be completed for bridges undergoing preservation/rehab work so that the Structures Management Unit can update their records accordingly.

ENGINEER ACCEPTANCE REPORT

When all or a portion of a project is complete and ready to be accepted in accordance with Article 105-17, the Engineer Acceptance Report form shall be completed. This form can be used for bridge Deck & Rail Acceptance, Partial Acceptance (All work except vegetation or any other portion of the project), and Final Acceptance. The Area Construction Engineer utilizes this form on Centrally Let projects and the Resident Engineer utilizes the form on Division Let projects. This form should be completed within 72 hours of completion of the work being accepted.

The Engineer Acceptance Report form can be found in the individual projects Construction Team Site within each Division. The critical steps in the process are as follows:

For Centrally Let Projects

-

The Area Construction Engineer from the Construction Unit will fill out and complete the online Engineer Acceptance Report form

-

The Area Construction Engineer will submit an email with attached web link of the completed form to the Division Construction Engineer, Resident Engineer, and other personnel listed on the form

-

A letter will be generated by the Construction Unit notifying the Contractor of the Final or Partial Acceptance of the project

-

For Deck & Rail Acceptance, after receiving the form, the Resident Engineer will notify the Contractor in writing

For Division Purchase Order Projects (DPOC)

-

The Resident Engineer will fill out and complete the online Engineer Acceptance Report form

-

The Resident Engineer will submit an email with attached web link of the completed form to the Division Construction Engineer and other personnel listed on the form

-

A letter will be generated by the Division notifying the Contractor of the Final or Partial Acceptance of the project

-

For Deck & Rail Acceptance, after completing the form, the Resident Engineer will notify the Contractor in writing

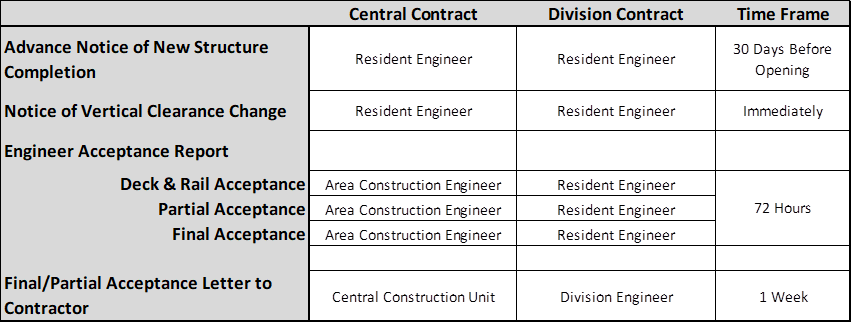

The following responsibility chart should be followed:

![]()

When a portion or all of the Contract has been accepted, including Deck & Rail acceptance, this begins the 12 Month Guarantee Provision detailed in the Project Special Provisions. This is tracked in the Project Guarantee tab under Review Contract Details in HiCAMS. This information should be entered in accordance with the responsibility chart listed above.

[top of page]

CC LIST FOR ACCEPTANCE AND STRUCTURE NOTIFICATION FORMS

CENTRALLY LET CONTRACTS

Engineer Acceptance Report (Partial, Final, Deck & Rail Acceptance)

-This is the old Construction Engineer Inspection Report and is renamed in SharePoint

AREA CONSTRUCTION ENGINEER SUBMIT ENGINEER ACCEPTANCE REPORT TO: